Product List☰

Product

Product Name:Pneumatic Vacuum Cleaners

Brand:JS1000D JESON Centralized Dust Removal Systems

Product Brief:

- Centralized Dust Removal Systems.

- For car repair plant.

- Can use up to 3- 4 people in the same time.

- Side channel blower.

- Long- term operation.

- Made in Taiwan.

|

Model |

: |

JS1000D |

||

|

Voltage |

|

3P/380V/60Hz |

3P/380V/50Hz |

|

|

Consumption Power |

: |

3.7KW*2 (DUAL MOTORS) |

3.4KW*2 (DUAL MOTORS) |

|

|

Max Vacuum |

: |

3000 mmH2O ±15% |

2600 mmH2O ±15% |

|

|

Air Flow |

: |

6.2 m³/min |

5.2 m³/min |

|

|

|

|

10.5 m³/min |

8.8 m³/min |

|

|

Electric Current |

: |

15.6A |

14.4A |

|

|

Operating Noise |

: |

73dB (at 3M) |

||

|

Drum Capacity |

: |

58 L |

||

|

Measurement(LxWxH) |

: |

1400x680x2100 (mm) |

||

|

Weight |

: |

300 kgs |

||

|

………………………………………………………………………………………………………………………………………… |

||||

|

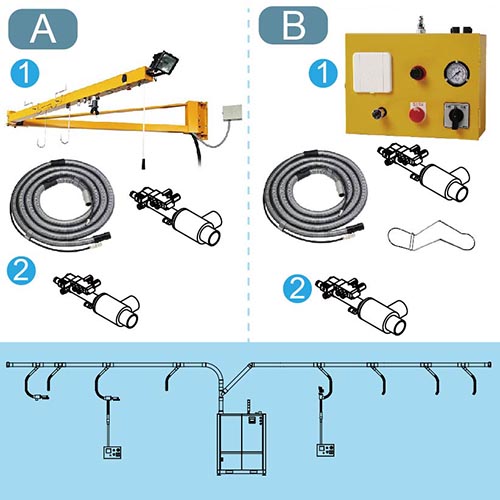

To purchase with following plans: 1) JS1000-1 2) Solenoid-valves & Throttle

valve*1set Plan B: 1) JS1000-2 2) Solenoid-valves & Throttle

valve*1set |

||||

|

………………………………………………………………………………………………………………………………………… |

||||

|

JS1000D Specifications: 1) Transmission by internet, provide the signal to working system. 2) By the internet to check the programs without delay, offer prompt advise services. (Customers must have IP address.) (Option) 3) Automatically clean filter. 4) According to the setting of the work station to start up dual motors. 5) Depends on customer’s needs, setting time to shake off the dust, blow reversely to clean the filter in order to extend the life span of the filter and keep the max suction power. 6) Equipped with pressure release settings to release pipe pressure. 7) According to independent work station’s demand adjust the motor. 8) Reverse valve controlled by digital control module ensure the action correctly. 9) Filter cleaning by shaking will not interrupt operation. 10) 58 liter stainless container with u-shape rubber sealing prevents dust from leaking. 11) With an auto detector, after Vacuum tank returning to its position, pneumatic valves will open and lower the sealing cover. 12) With high voltage blow motors, better dust collection, High static pressure, bigger air flow, low noise, and strong suction 13) Automatically on, delay switch, and overload protection Motor operation time with energy saving design increase life span of motors. 14) Decrease environment pollution and improve the cleanness of the factory. 15) With high-density filter increase the life of the motors. 16) Four persons in use simultaneously will weaken the suction. |

||||

|

………………………………………………………………………………………………………………………………………… |

||||

|

JS1000-1 Specifications: Set up the hoses, wires in the arm, far away the ground, offer a dust-free environment and air-clean quality while working. 1) Radius 5.5M, circle round 180 degrees. 2) Two start-up controls: manual or automatic. 3) 【Vacuum suction automatic blocking system】makes sure the suction supply only being used for the sander, increased suction effect. 4)

Supply the powerful suction. |

||||

|

………………………………………………………………………………………………………………………………………… |

||||

|

JS1000-2 Specifications: 1) 【Vacuum suction automatic blocking system】makes sure the suction supply only being used for the sander, increased suction effect. 2) The station is equipped Auto/Manual Switch for different demands. 3) Equipped with air flow adjustment valve and manometer. 4) With an emergency power switch. (cut off the power in case of anything emergency) |

||||

|

………………………………………………………………………………………………………………………………………… |

||||

|

Solenoid-valves & Throttle valve Specifications: The system stays on for 6 to 8 seconds by throttle and solenoid settings to make sure the dust is out of the hose after turning it off. |

||||